NAV×

Machine advantages

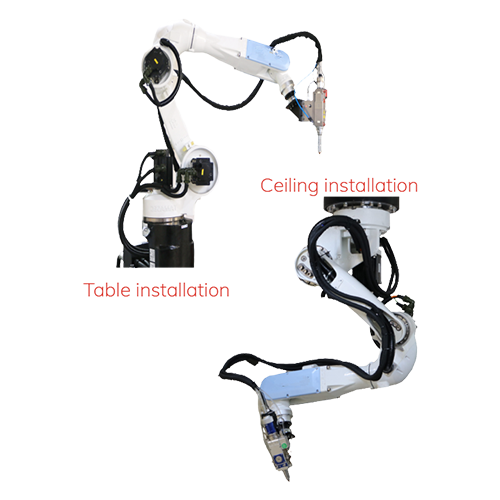

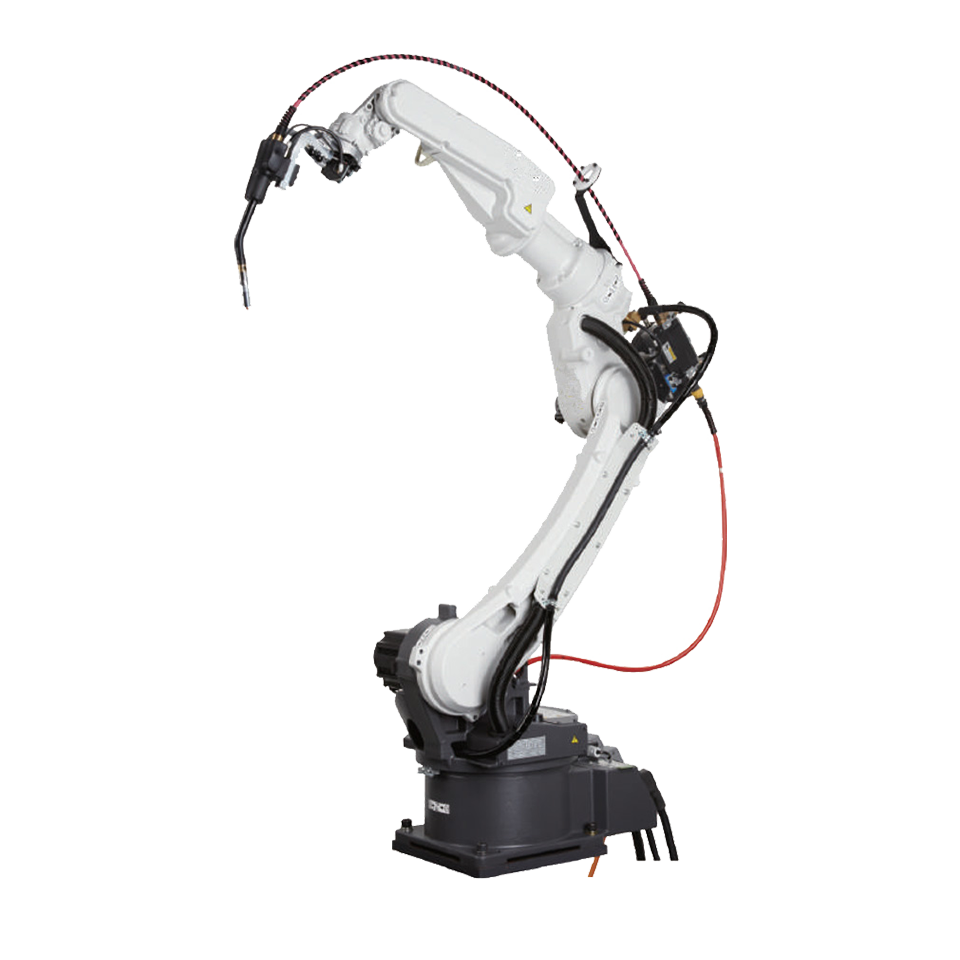

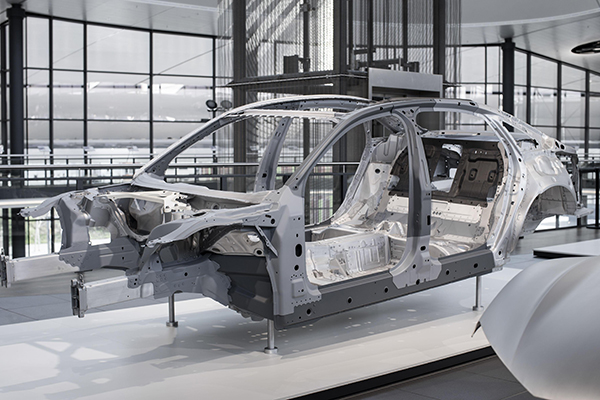

Today, welding is an innovative mounting technique that is used in all areas. While the technique itself is widespread, some of its processes are not yet as well known and under used. Laser welding falls into that category and, despite its false reputation as a complex process, offers many unparalleled advantages in terms of speed, technology and costs. Compared to traditional manufacturing processes such as resistance spot welding or conventional ARC welding, Fiber Laser Welding offers easy operation, very simple to learn with a fast learning curve, improved energy efficiency, smaller ecological footprint, lower maintenance requirements, less environmental contamination, improved machine lifetime and faster cycle times for high-volume production. Consequently, the processing speed is maximized; material costs and operation costs are minimized. The precision provided by fiber lasers is particularly useful for manufacturers switching to precise, thin-walled and lightweight designs made of light or very resistant materials. Significant weight reduction is achieved by minimizing the size of parts and components via fiber laser welding, while safe engineering is fully enabled by wobble-beam fiber welding.

PRODUCTS VIDEO

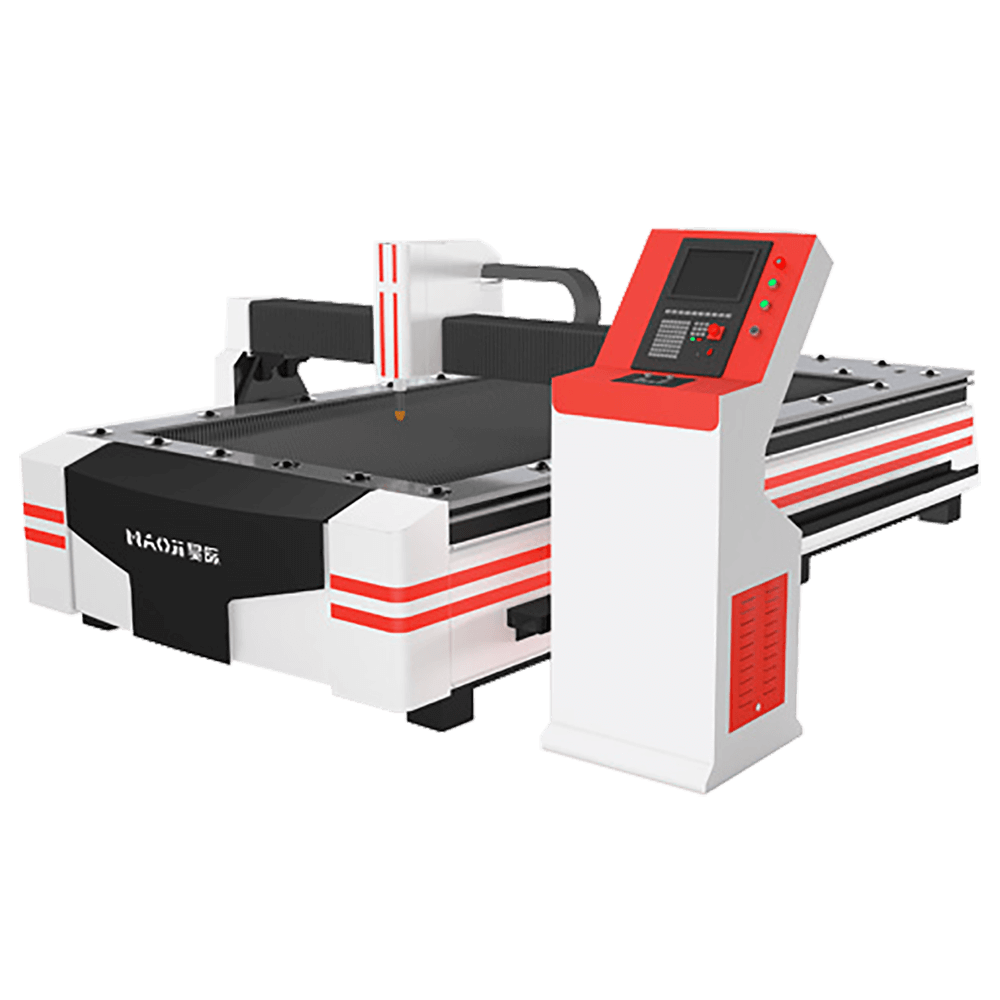

Technical Parameters

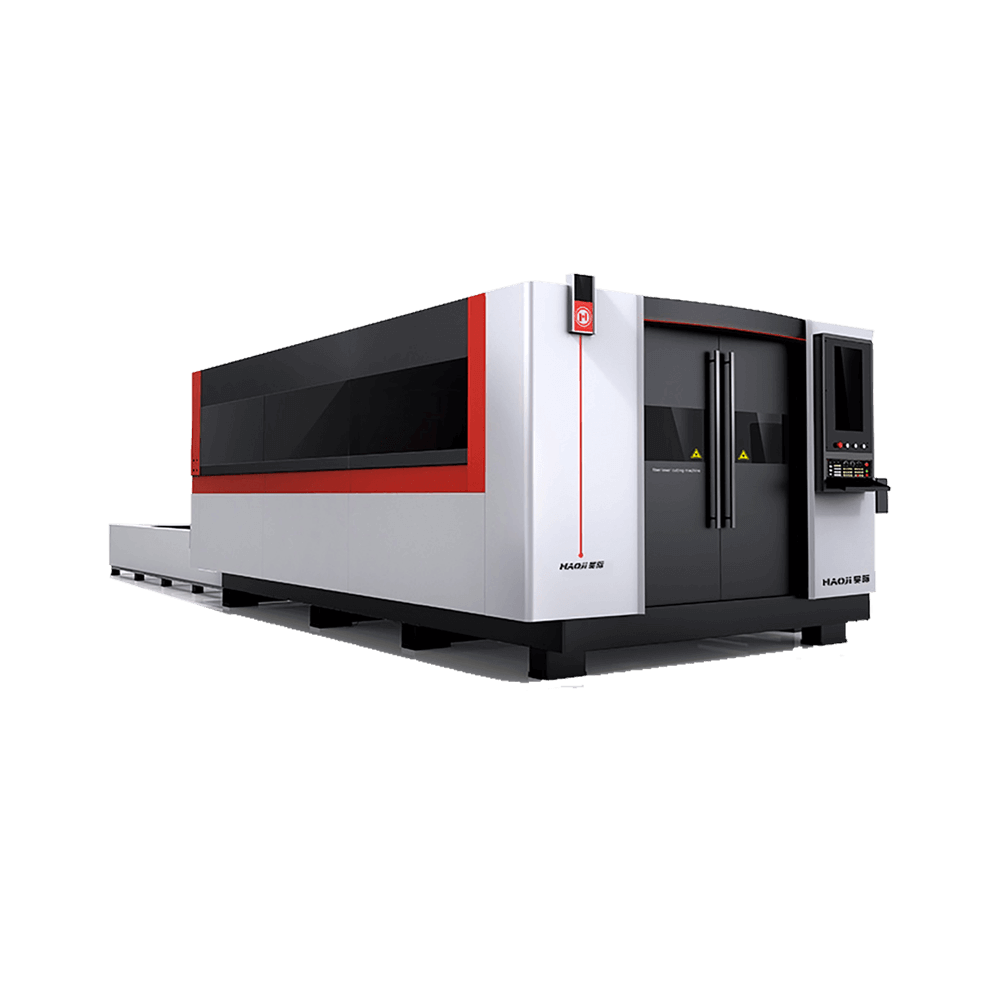

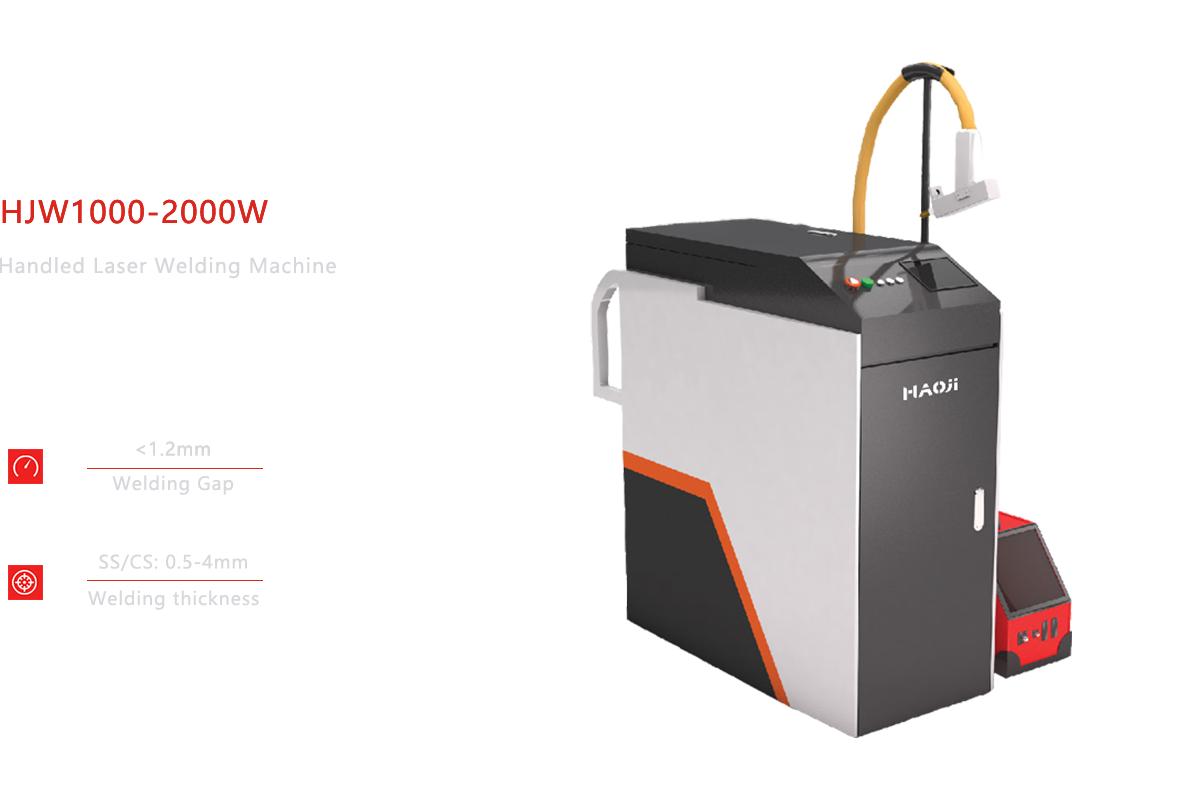

| Model | Laser wavelength | Working model |

| HJW | 1060-1080nm | Continuous/ Pulse |

| Welding Gap | Welding thickness | Positioning |

| <1.2mm | SS/CS: 0.5-4mm | Red light positioning |

| Working voltage | Laser power | Machine dimension |

| AC380V/220V | 1KW - 2KW | 1240*620*1060mm |

Download Zone

More downloadsApplication industry

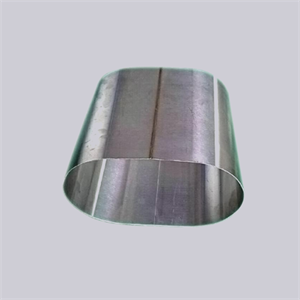

Kitchen appliances,sheet metal case cabinets,machinery equipment,electrical equipment,lighting hardware,advertising signs,auto parts,display equipment,various metal products,sheet metal cutting and processing industries.